Robotics in Production: Boosting Efficiency and Minimizing Human Errors

Author: Варвара Вавилова

In today’s fast-paced manufacturing environment, robotics is playing a crucial role in transforming production processes. The integration of robotics into production lines is not only increasing efficiency but also significantly reducing human errors. As technology advances, robots are becoming more sophisticated, capable of performing complex tasks with precision and speed that were once unimaginable. This shift towards automation is driving the manufacturing industry to new heights of productivity and quality.

One of the most significant benefits of incorporating robotics into production is the dramatic improvement in efficiency. Robots are designed to perform repetitive tasks with consistent speed and accuracy, far surpassing the capabilities of human workers in these areas. By taking over routine and time-consuming tasks, robots free up human employees to focus on more complex and creative work. This division of labor leads to faster production times, higher output, and the ability to meet growing consumer demands more effectively.

In addition to boosting efficiency, robotics also plays a crucial role in reducing human errors in production. Even the most skilled workers can make mistakes, especially when faced with repetitive tasks that can lead to fatigue and decreased attention to detail. Robots, on the other hand, are immune to these issues. They can work continuously without breaks, maintaining the same level of accuracy and precision throughout the production process. This consistency leads to fewer defects, higher-quality products, and reduced waste, ultimately saving companies both time and money.

Robotics also enhances safety in the workplace by taking on tasks that are hazardous to human workers. In industries such as automotive manufacturing, chemicals, and heavy machinery, robots are used to handle dangerous materials, operate in extreme environments, and perform tasks that pose a high risk of injury. By reducing the need for human involvement in these high-risk areas, companies can minimize workplace accidents and ensure a safer working environment for their employees.

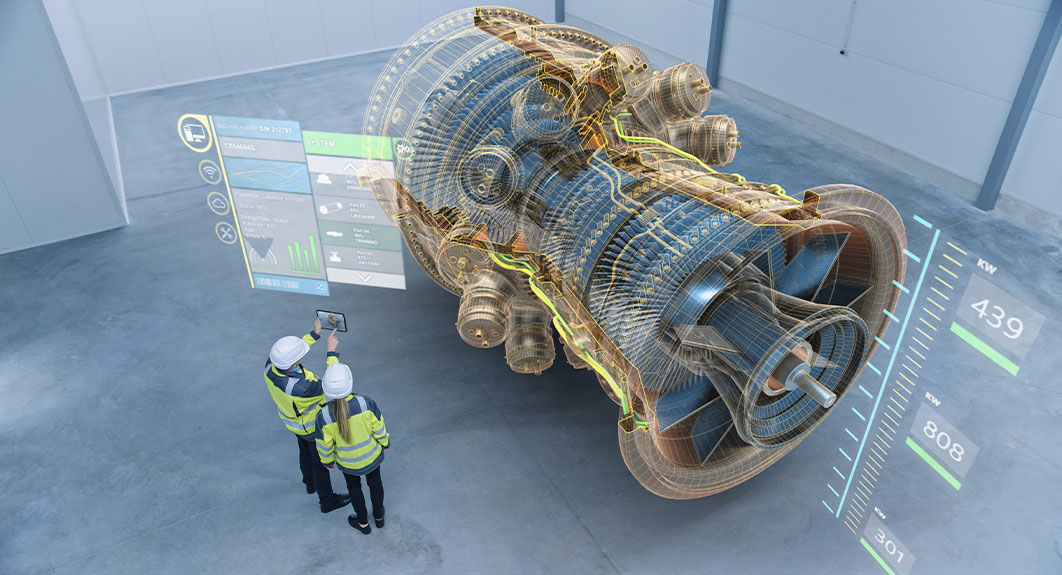

Another key advantage of robotics in production is its ability to adapt to changes in demand and production needs. Modern robots are equipped with advanced sensors and AI capabilities that allow them to adjust their operations in real-time. This flexibility is particularly valuable in industries that require frequent changes in product design or customization. Robots can be reprogrammed or reconfigured quickly, allowing manufacturers to switch production lines with minimal downtime and respond rapidly to market shifts.

The integration of robotics into production also paves the way for increased innovation and continuous improvement. With robots handling the bulk of routine tasks, companies can invest more in research and development to explore new production techniques, improve product designs, and enhance overall operations. The data collected by robots during production can be analyzed to identify areas for further optimization, leading to ongoing improvements in efficiency and quality.

In conclusion, robotics is revolutionizing the production industry by increasing efficiency, reducing human errors, and enhancing safety. As robots continue to evolve and become more integrated into manufacturing processes, the potential for further advancements in productivity and quality is immense. Companies that embrace robotics in their production lines are not only positioning themselves for success in today’s competitive market but are also paving the way for the future of manufacturing.

Popular Articles